Servo Motor

Repair

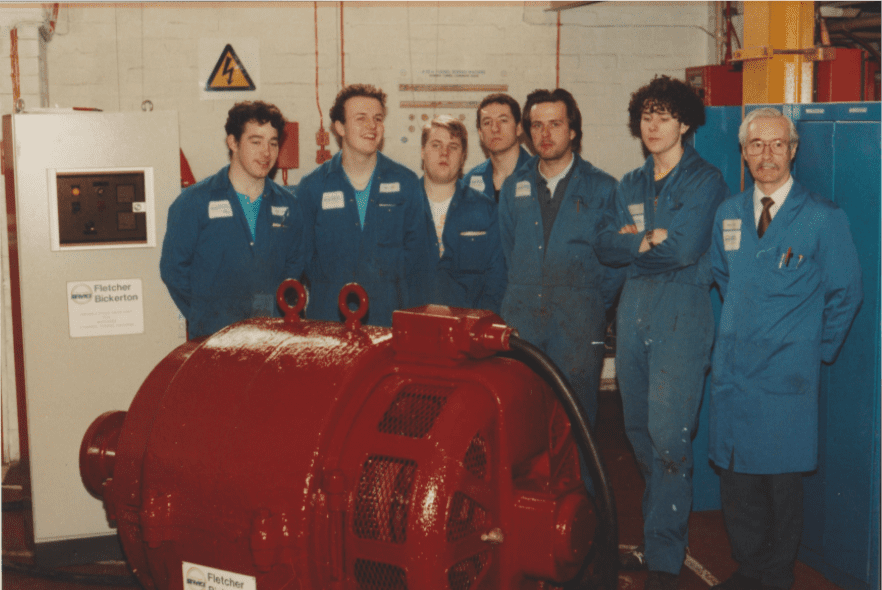

It was back in the early 1980s that we setup a servo motor repair department. they were much more simple back then than they are now however techniques to repair them were not widely understood.

We were the pioneers of servo motor repairs in the UK. It was interesting figuring out how they worked and designing test facilities for them. It’s our 35+ years’ experience in servo motor repairs that really does give us an authority in the trade.

We would not simply say ‘of course we can repair your servo motor!’

Critical Part

of Success

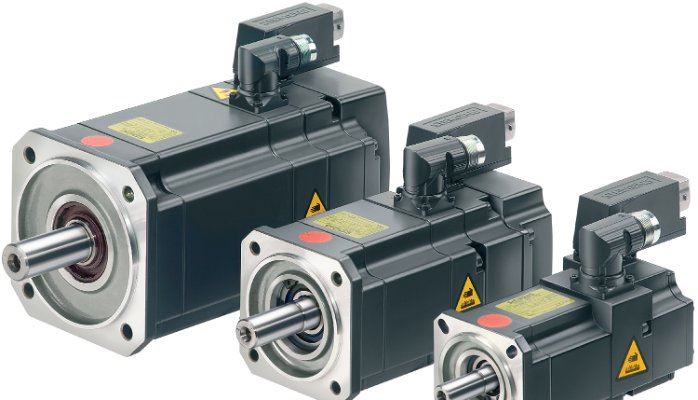

There are thousands of types out there, after all we’ve seen thousands of them, so we know. Each type requires different diagnostic equipment to firstly test the servo motor, repair it, then to run test it afterwards. Back in the good old 80s and 90s most servo motors were encoder or resolver types and it was the alignment of these that was most important.

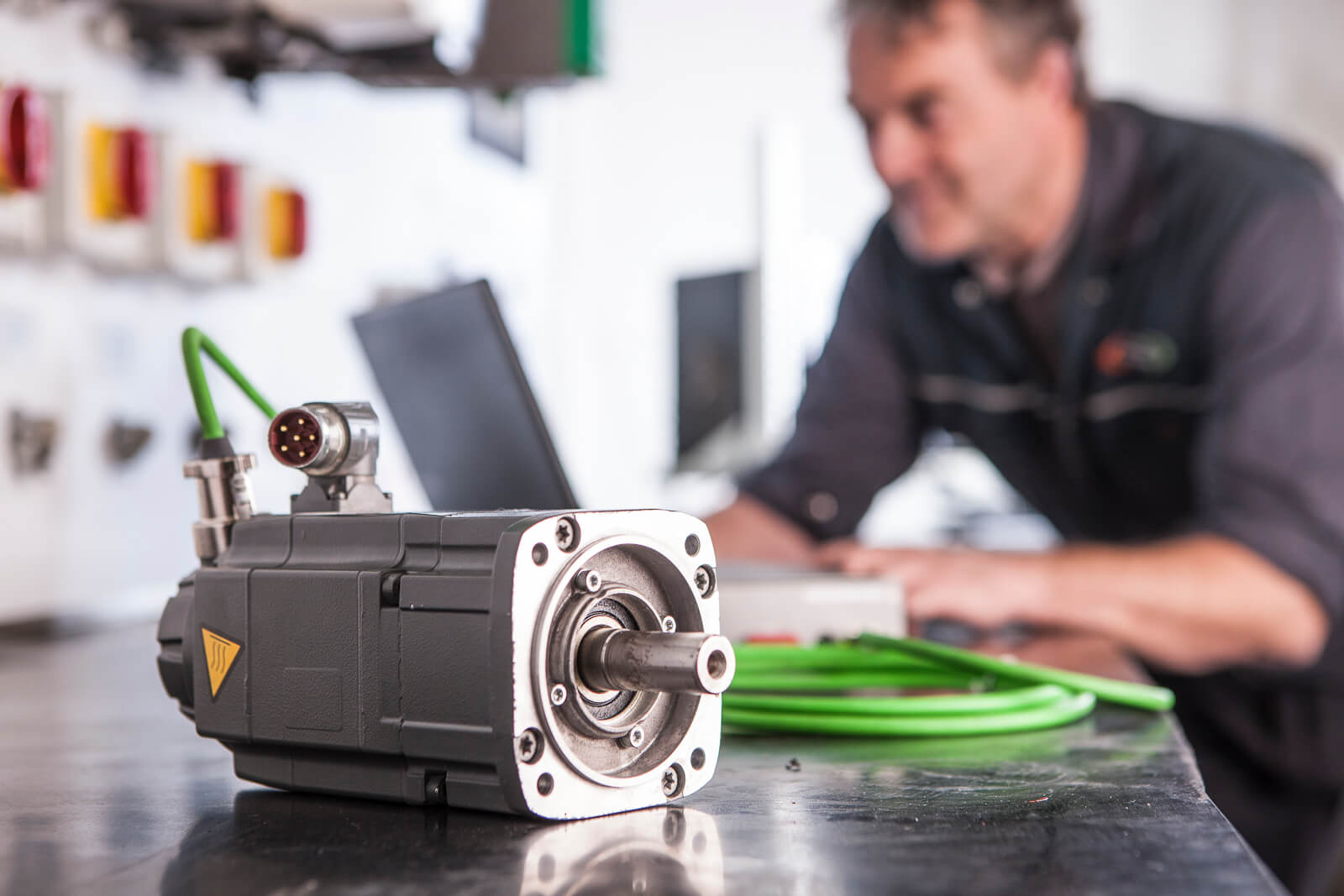

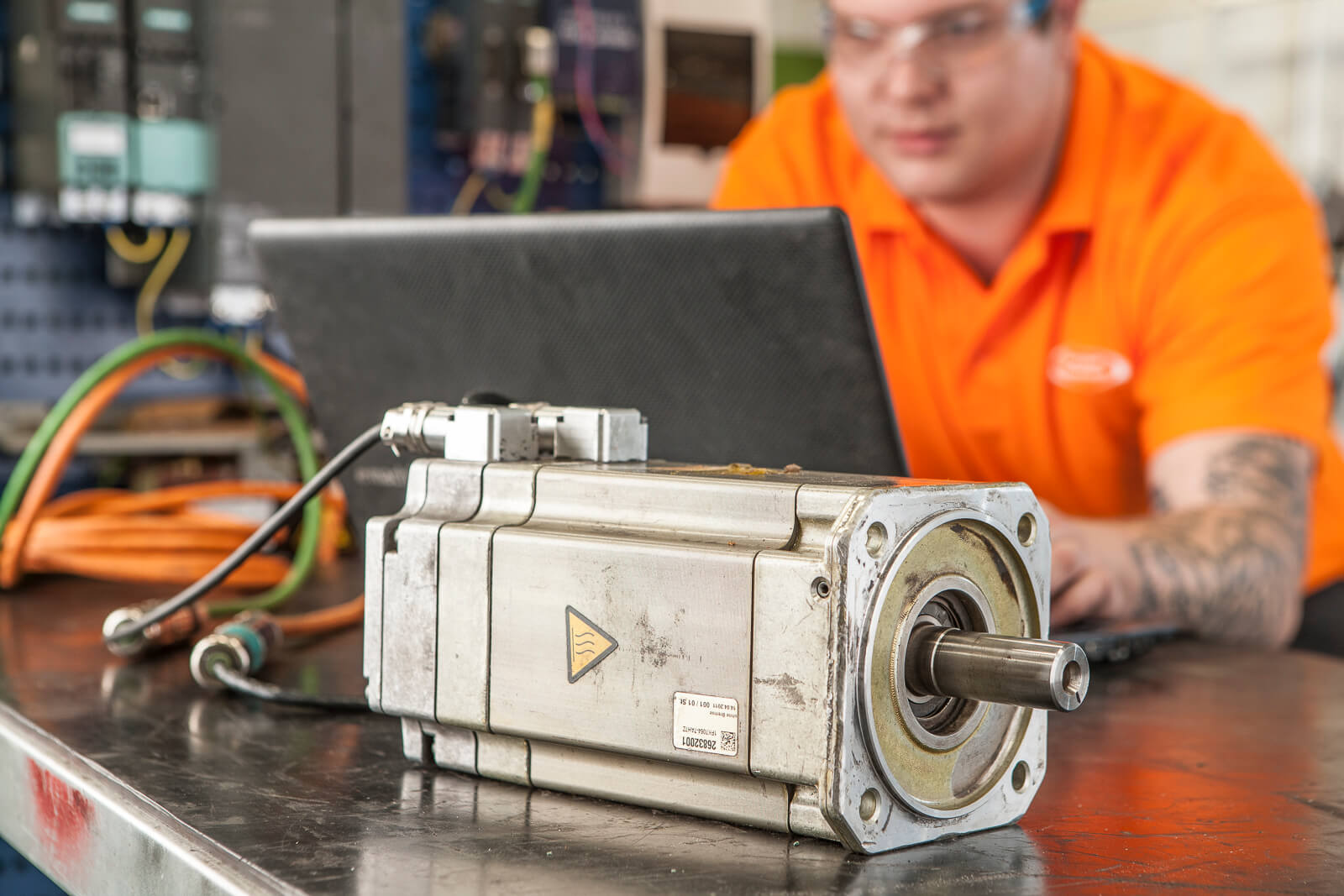

Nowadays most of the servo motors we repair have electronic nameplate data held within programmable encoders. It’s understanding how each type works and what’s needed to successfully repair them. We’re good at that.

Servo motors are still electric motors. Having an electric motor repair workshop alongside our servo repair workshop is crucial for us. After all, over 60% of the servo motors we repair require either a rewind or mechanical work to the shaft and/or bearing fits, or brake assembly. The most critical part of a successful servo motor repair is the final testing.

We have a dynamic load test rig. That basically means we are able to test your servo motor in a way that it would perform on your machinery. It tests the servo motor to full power in each direction and checks the holding and breakaway torque of the brake too, all at the nominal operating temperature of the servo motor. What’s more, we will take a video of the test being carried out to prove the repair to you.

Key services

- lAC & DC servo motors

- Spindle motors

- Stepper motors

- Combination drive/servo motors

- Dynamic load testing to 60Nm

- Dynamic brake testing

- Full mechanical refurbishment

- Class ‘H’ rewinds

- Encoder re-programming

- Drivecliq module reprogramming

- Re-magnetising facility

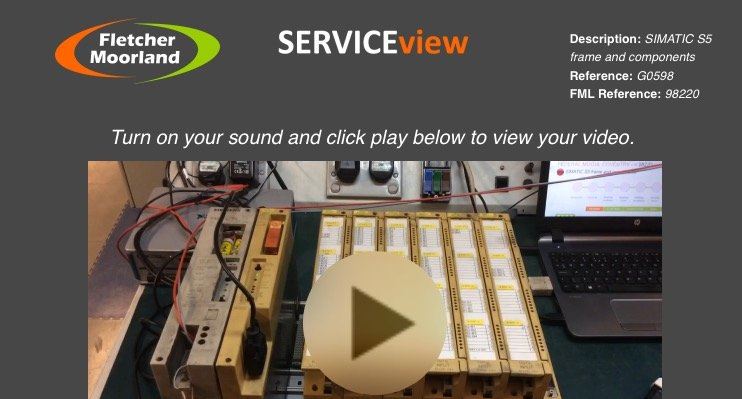

- SERVICEview videos of testing

- Sick/Stegman programming

- Heidenhain programming

- Mitchell TI300 & TI5000

- 12 month standard warranty

- 35+ year experience

Servo Motor News

Autostore Robot AS-35085 servo motor refurbishment

News, Servo Motor RepairAutostore AS-35085 robot motor refurbishmentAutostore robot motors (part number AS-35085) are used on many of the Autostore robot units in distribution, sorter and pick systems worldwide. The motors are an Engel GNM8070/4 permanent magne...

How a LinkedIn post resulted in a stepper motor repair for us

News, Obsolete Equipment, Servo Motor RepairThis is a LinkedIn success story where a referral enabled us to help a new customer. We were tagged into a post after a LinkedIn member posted a picture and a simple request for a motor repair. We replied to the post, along with many oth...

A motor repair with some interesting UK engineering history

General, News, Servo Motor Repair, engineering historyRecently, there was a great deal of interest in an article I wrote about the resurrection of a DC motor. This reminded me of a much more interesting recovery and refurbishment of a DC motor. Let me start with a bit of history In the 19th...

Before and after of a DC Motor Repair

News, Servo Motor Repair, Dc motor, DC motor repair, servo motor repairA few week ago I posted a photo of a failed DC motor where the commutator has failed and taken out the brush gear. The failure was quite spectacular and the photo prompted many, many comments. I promised to post an ‘after’ photo when the...

Having a ‘can do’ approach really pays off when supporting customers

Electric Motor Repair, General, HMI Repair, News, Servo Motor Repair, Servo Spindle Repair, equipment repair, motor repair, SERVICEviewAs happens most Saturday mornings at Fletcher Moorland, the phone starts to ring and there’s a customer on the line with an urgent breakdown which needs sorting. Most calls at the weekend will be calmly and professionally handled by Jenn...

SERVICEview – Transparency in the repair industry

Automation Repair, Electric Motor Repair, General, HMI Repair, News, Servo Motor Repair, Servo Spindle Repair, industrial, repair, repair industry, SERVICEview, servicingWouldn’t it be great to see exactly what happens when you send equipment for repair or servicing? We’ve created SERVICEview for greater transparency and trust for our customers. Now, when you send an item of equipment away for servicing ...

Servo Motor Repairs; why electrical, electronic and mechanical skills are needed

General, News, Servo Motor Repair, servo motor repairServo motors are very specialist and high precision motors. They contain both precessions mechanical and miniature electronic components. Repairs to them require a specialist set of skills in electronic, electrical and mechanical repair...

Getting ABB servo repairs right

General, News, Servo Motor Repair, ABB servoRobot servo motors are critical to plant operation and production, Our customer who is a major automotive parts supplier had sent this ABB servo motor to his motor rewind company, who did in fairness say they could not repair servo motor...