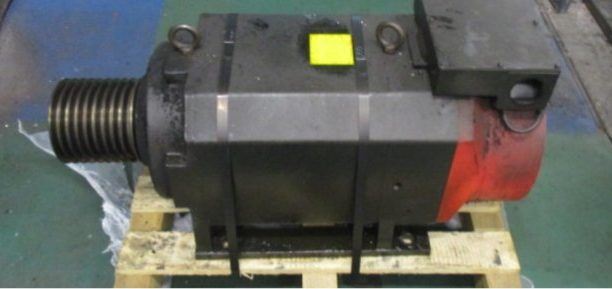

A number of you were commenting and asking questions about the Fanuc Spindle motor we had in for urgent repair over the weekend and I wanted to answer all the questions received.

The motor part number is A06B-1455-B200 It is a 4500 rpm main spindle motor for a CNC machine. Year of manufacture was 2007 and the motor had not been out of service since the machine was installed.

Now there was no catastrophic failure of the machine, the customers in-house VA team identified a fault (we don’t as yet have the information as to what they suspected) however due to their 24/6 production schedule they couldn’t afford a failure in service so they created an outage window which was over the weekend just gone. The motor was very dirty as can be seen in the top photograph. We were expecting to see some issue with the bearings. (We know these machines have sealed-for-life-bearings, so no possibility of re-lubricating in service) but on strip down we found a loose balance ring on the drive-end side of the rotor. These machines have a balance ring shrunk-fit to either end of the rotor, just underneath the rotor shorting rings. As this was loose I can see how a VA team picked up a problem. Our repair was to remove the ring, sleeve it and shrink fit back to the rotor. We measured all the bearing fits to micron tolerance with our coordinate measuring machine. Balanced the rotor to G1.o (ISO1940:1). Fitted new bearings and assembled the motor. As this motor is a specialist spindle motor it has a hall effect pick-up sensor on the non-drive-end. We fitted this and adjusted the sensor to give the required voltage levels for all the outputs on this motor (sine/cosine wave). The cooling fan was serviced too and fitted to the motor and we carried out a final test to ensure all our vibration specification levels were within tolerance. The motor was painted and shipped back to our customer this morning at 5am for his production start at 8am.

The main question – Why did the balance ring become loose? I don’t know, we may never know, I can only make a best judgment on this occasion and say that I suspect the fit from new wasn’t what it should have been. Incidentally, the customer has only just started to carry out a VA program on these machines so in all probability, it may have been like this for a while.