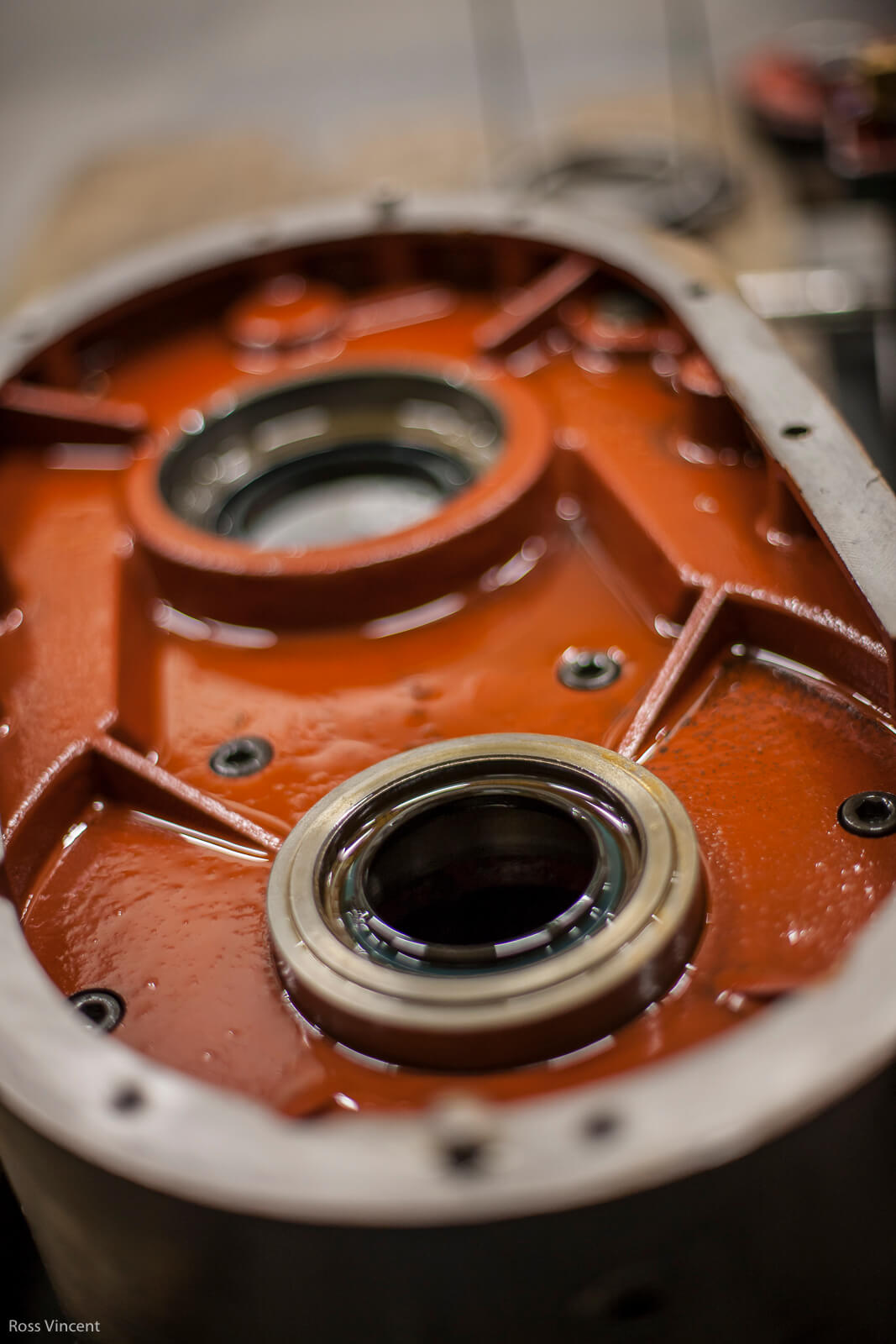

Gearbox

Repair

Whether it’s a small sew unit that you can pick up in your hand or one that weighs 10 tonnes and needs a crane to lift it, we have the skills and equipment to repair and service it.

Quite often gearbox repairs are minor with them requiring a bearing, seal and oil change to bring them back into a serviceable condition. There are those occasions though when gears are damaged, shafts snapped or bent and housings are worn.

Precision

Engineering

Gearboxes are complex, precision pieces of engineering and we treat them as such. Co-ordinate measuring machines capable of measuring down to 2-3 micron accuracy are used to measure all critical dimensions on gears, housings, keyways and shafts so we can accurately judge the condition of your unit. If new gears need to be cut, new shafts manufactured, or the housings needs to be reclaimed, it’s all taken care of by us.

What our customers do find interesting is the SERVICEview video we shoot to give you a condition report of the gearbox as we receive it. We’ll let you know exactly what we find wrong and give our assessment of what may have caused any failure to help your reliability teams get greater life when it’s re-installed on your site.

Key Services

- Oil Analysis

- Condition Monitoring

- Thermography

- Re-design

- Full overhauls

- Serviceview video to report condition and diagnosis

- Repairs to:

- Worn gear trains

- Worn & broken gear teeth

- Sheared output shafts

- Worn bearing journals/housings

- Damaged casing

- Oil contamination

- Worn key way

- Seal failures

- Units up to 10 tonnes