Ok, maybe not a typical opening to a website post but it’s a good one. Here’s an example of something that any user of electric motors doesn’t want to see at all on their motor’s bearings. The ‘old favourite’, signs of circulating shaft current damage. The typical example that we’ve probably all seen in photos is the fluting or washboard …

Why multimeters shouldn’t be used to test large electric motors

Why in-field testing an electric motor with a multimeter might not be such a good idea. We had a call-out to a customer over the bank holiday weekend where they were having trouble with an inverter tripping each time it tried to drive a motor. The information we had from the site engineers was that the motor tested ok and …

Holes in electric motor windings?

These holes are meant to be here though.This feature in an electric motor winding is unusual but not uncommon. They are there to serve a purpose. This type of motor is used in electric vehicle propulsion. It is the guts of a BAE Systems Hybridrive TB08 electric traction motor. All electric motors need to be cooled and most standard motors …

Does rewinding reduce electric motor efficiency?

This 4 minute video explains why rewinding an electric motor does NOT reduce efficiency….providing it is done correctly with the correct processes, tools and follows the strict guidelines set out by EASA & AEMT. Here’s a link to the guidelines if you wish to read for yourself – Motor rewind efficiency study

“Should I repair my electric motor or should I replace it?”.

This question is asked around the world every day. And the answer? Well, the answer you will get depends on who you ask. And, If you’re the one responsible for getting your plant back up and running again, the answer might not be in your best interests either. Just consider this for a moment. You ask two people that same …

These electric motors help reduce vehicle emissions.

It’s more by accident rather than by design that my recent posts have featured technology and processes that are environmentally friendly. This one, as it so happens, is the same. We’re all I expect very used to traditional electric motors in my posts, but here’s one that is a little different. If you’ve not seen one of these before, it …

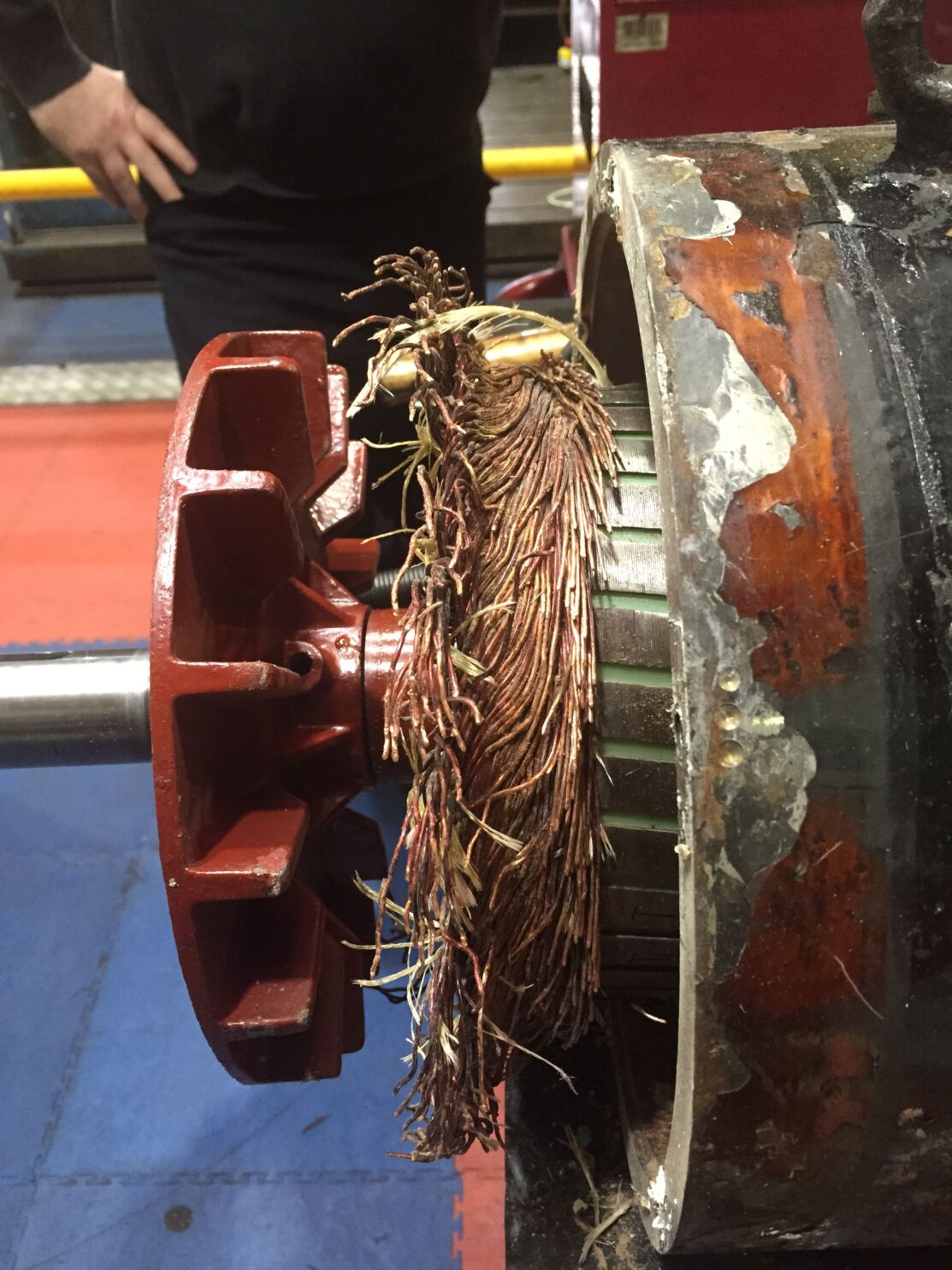

It’s not just DC motors that need regular brush inspection and maintenance.

There is a type of AC motor in industry that you may have hidden away in your process plant that has brushes in too. These are known as slip-ring motors. They are often referred to as wound-rotor motors too. That description probably explains more of the construction of the motor then slip-ring does actually. Instead of having cast rotor …

10 preventative maintenance tips to keep your DC motors running.

DC motors need preventative maintenance, they are not fit-and-forget electric motors. Unlike their AC motor counterparts, DC motors have wearing components that need to be checked regularly. By carrying out regular simple preventative maintenance tasks you can reduce the chance of an in-service failure massively. First of all, REMEMBER SAFETY, all equipment should be isolated and a safe working method …

Is this possibly the cheapest reliability invention ever created?

Is this possibly the cheapest reliability invention ever created? Yes, I’m serious, the humble grease nipple cap. It costs pence but can save you thousands…… Think about it and what it does, it protects contaminants from getting into the lubricant. Next time you walk around your plant, take a look at your equipment. How many grease nipples can you see …

Overspeed on a series wound DC machine, a lesson learnt

Well, it seems I’ve generated a great deal of interest with my post regarding an accidental over speed of a DC motor we had repaired. Just last week, I posted a photo of a DC motor armature after it had been accidentally overspend, after we had rewound it. Here’s the original post A great learning experience I posted it to …

- Page 1 of 2

- 1

- 2