Electric Motor

Repair

A very simple philosophy runs throughout our electric motor repair workshop, that all repairs and rewinds are to be as good as, if not better than new.

It’s not just something we say. We can prove it. Head to our website to take a look at our electric motor repair specification. Not all rewind companies do the same thing or work to the same standards. Ours is there with the best in the trade. We can say that with confidence too. We’ve achieved the EASA Accreditation for assuring the efficiency and reliability of repaired electric motors. We hold the IECEx certified service facility certificate for Ex equipment repairs. A recent highlight is ABB recognising us as one of their Value Providers for electric motor sales and service. You benefit from our high standards too, we give a three-year guarantee on 3 phase AC motor rewinds, that’s often higher than many OEMs.

Refurbish

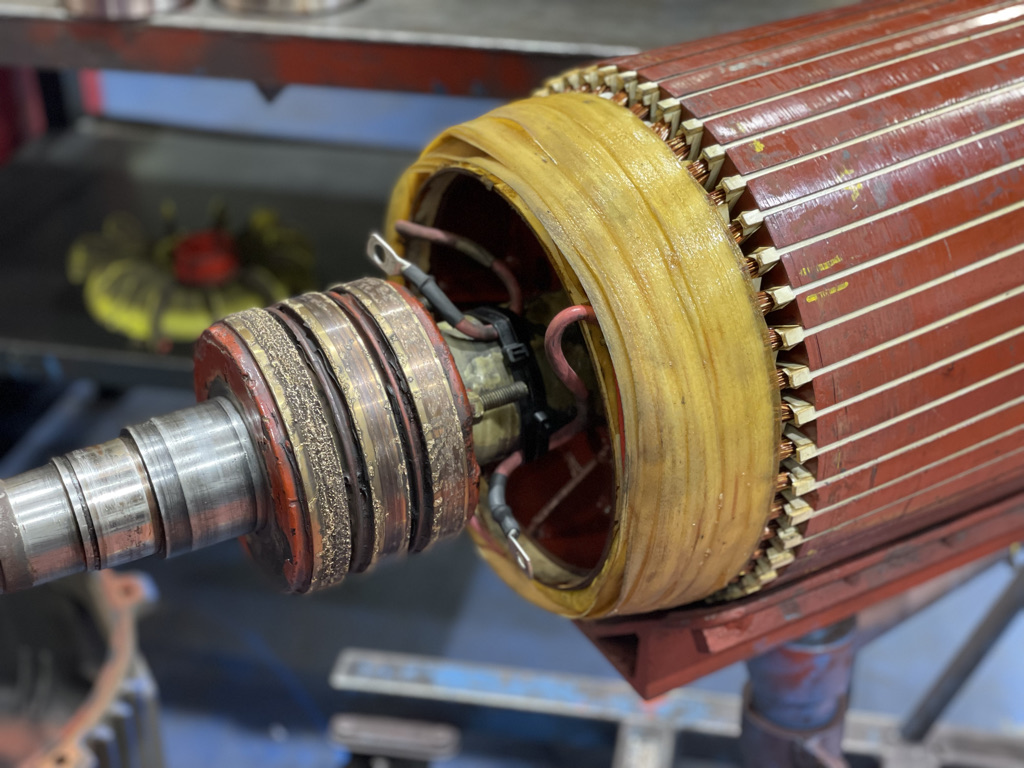

Reliability of our repairs is key. We don’t just repair your equipment, we will fully refurbish it and add-in reliability improvements to make sure your motors run smoother and last longer. Such things as using class ‘H’ insulation in our rewinds which is a superior grade to standard OEM class ‘F’. We will balance all rotating items to G1.0 balance grade which is superior to most new motors. All bearing journals and housings will be measured to ISO tolerances using a coordinate measuring machine. After all, over 50% of motor failures are bearing related. We find this is an area most often overlooked and must contribute to this fact.

When we’ve returned a motor to you, we’re not really interested in seeing it again. That’s why we have a dedicated reliability team here to help keep your motors running. These guys can help with correct installation and alignment, site improvements and upgrades, also monitoring the motors to ensure you get the best out of them.

Key services

- Lifting up to 10 Tonnes

- AC motor rewinds to 3.3Kv

- DC motor rewinds to 1000v

- Linear and turntable motor rewinds

- ABB Value Provider

- Ex Motors – IECEx certified service facility

- EASA Accredited repair

- Class ‘H’ insulation as standard.

- Bearing fit measurement to 2-3 microns

- VPI as standard

- 12Kv Baker Advanced

- Winding Analyser

- Load testing to 350 Amps

- Controlled pyrolysis oven to maintain motor core efficiency

- De-gaussing & temperature controlled bearing heater

- FAG & SKF bearings as standard

- Lexseco core loss tester

- Enhanced G1.0 balance grade

- SERVICEview video to report condition and diagnosis

- Vibration and conformance check report

Motor repair News

Now that’s a pair of balls!

Electric Motor Repair, Linkedin, NewsOk, maybe not a typical opening to a website post but it's a good one. Here's an example of something that any user of electric motors doesn't want to see at all on their motor's bearings. The 'old favourite', signs of circulating shaft ...

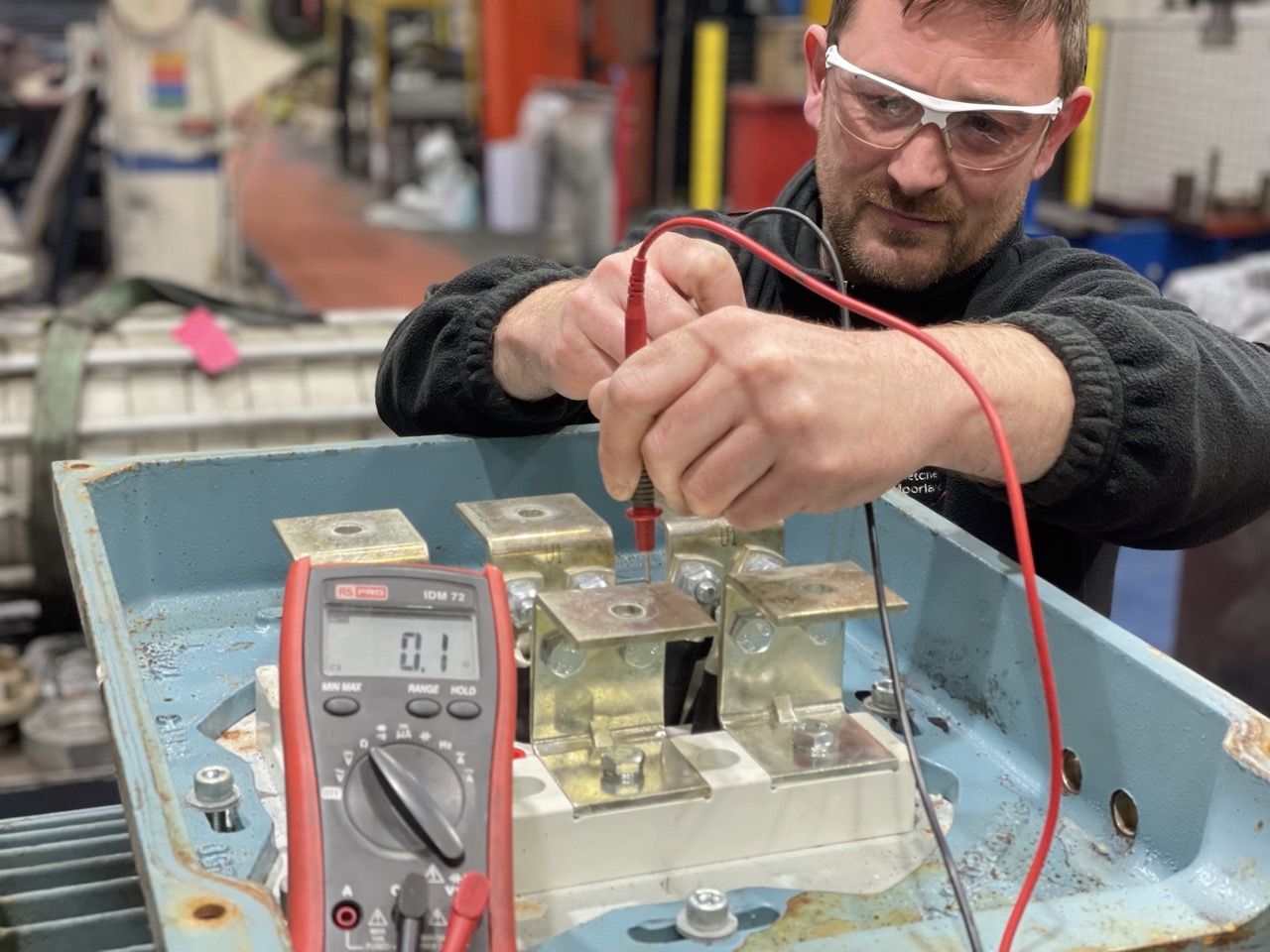

Why multimeters shouldn’t be used to test large electric motors

Electric Motor Repair, Electro Mechanical, General, LinkedinWhy in-field testing an electric motor with a multimeter might not be such a good idea. We had a call-out to a customer over the bank holiday weekend where they were having trouble with an inverter tripping each time it tried to drive a ...

Holes in electric motor windings?

Electric Motor Repair, GeneralThese holes are meant to be here though.This feature in an electric motor winding is unusual but not uncommon. They are there to serve a purpose. This type of motor is used in electric vehicle propulsion. It is the guts of a BAE Systems ...

Does rewinding reduce electric motor efficiency?

Electric Motor Repair, News, electric motor repair, RewindersThis 4 minute video explains why rewinding an electric motor does NOT reduce efficiency….providing it is done correctly with the correct processes, tools and follows the strict guidelines set out by EASA & AEMT....

“Should I repair my electric motor or should I replace it?”.

Electric Motor Repair, General, NewsThis question is asked around the world every day. And the answer? Well, the answer you will get depends on who you ask. And, If you’re the one responsible for getting your plant back up and running again, the answer might not be in yo...

These electric motors help reduce vehicle emissions.

Electric Motor Repair, General, NewsIt’s more by accident rather than by design that my recent posts have featured technology and processes that are environmentally friendly. This one, as it so happens, is the same. We’re all I expect very used to traditional electric mo...

It’s not just DC motors that need regular brush inspection and maintenance.

Electric Motor Repair, General, NewsThere is a type of AC motor in industry that you may have hidden away in your process plant that has brushes in too. These are known as slip-ring motors. They are often referred to as wound-rotor motors too. That description probably e...

10 preventative maintenance tips to keep your DC motors running.

Electric Motor Repair, NewsDC motors need preventative maintenance, they are not fit-and-forget electric motors. Unlike their AC motor counterparts, DC motors have wearing components that need to be checked regularly. By carrying out regular simple preventative ma...